Shaping the Future of Automotive Manufacturing: The Use of Gear Shapers

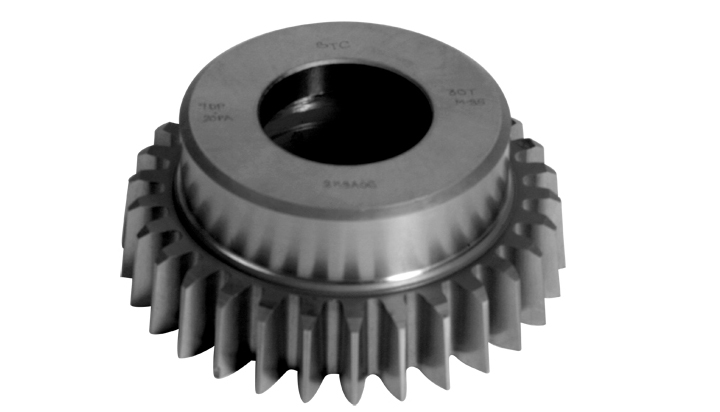

Gear shaper cutters are an essential component in the fabrication of gears, shaping gear teeth to exact specifications. These cutters are available in a variety of forms and sizes, as well as materials such as high-speed steel or carbide. Gear shaper cutter of various varieties are designed to generate certain gear types such as spur, helical, or bevel gears. Gear shaper cutters work by removing material from the gear blank while rotating the cutter and the gear blank in a shaper machine. This tutorial attempts to offer a thorough explanation of gear shaper cutters, including their many varieties, materials, advantages, and maintenance.

The Function of Gear Shapers in Automotive Manufacturing

Gear shapers use a shaping cutter to create the teeth of gears. These shaping cutters are designed to cut precise shapes and sizes, ensuring that each gear is uniform and functions properly. Gear shapers can also create gears with unique shapes and sizes to meet the specific needs of different automotive systems.

The Benefits of Gear Shapers in Automotive Manufacturing

The use of gear shapers in automotive manufacturing offers several benefits. First, gear shapers can create gears with high levels of precision, ensuring that each part functions properly and reduces the risk of failure. Second, gear shapers can produce gears quickly and efficiently, reducing manufacturing time and costs. Finally, gear shapers can create gears with unique shapes and sizes to meet the specific needs of different automotive systems.

The Role of Shaping Cutters in Gear Shaping

The shaping cutter is the key component in gear shapers. Shaping cutters are designed to cut precise shapes and sizes into the gear material, ensuring that each gear is uniform and functions properly. Shaping cutters are made from high-quality materials, such as carbide or high-speed steel, to ensure durability and precision.

The Importance of Quality Shaping Cutters in Automotive Manufacturing

Quality shaping cutters are essential to the manufacturing process in the automotive industry. Poor quality shaping cutters can result in defective gears that can cause system failure, resulting in costly repairs and potential safety hazards. Therefore, it’s crucial to choose shaping cutters from reputable manufacturers and ensure they are properly maintained and sharpened.

The Future of Gear Shapers in Automotive Manufacturing

As the automotive industry continues to evolve, the use of gear shapers is likely to become even more important. With the increasing demand for electric and autonomous vehicles, the need for precision gear manufacturing will only continue to grow. Therefore, the future of gear shapers in automotive manufacturing is bright.

In conclusion, gear shapers play a crucial role in the manufacturing process of the automotive industry. By using shaping cutters to create precise and uniform gears, gear shapers ensure that each part functions properly and reduces the risk of failure. With the increasing demand for precision gear manufacturing in the industry, the use of gear shapers is likely to become even more important in the future. Therefore, it’s essential to choose quality shaping cutters and invest in the latest gear-shaping technology to remain competitive in the ever-evolving automotive market.