acrylic fabrication in Sharjah: a brief overview

In this article, we will highlight the benefits of acrylic fabrication in Sharjah. In addition, we explain its importance in the construction industry.

What is Acrylic Fabrication?

Acrylic fabrication is a process of manufacturing acrylic products using various types of plastic film and resins. The film is then cut into specific shapes and heated to a high temperature, which causes the plastic to melt and fuse together. This creates the finished product, which can be used for a variety of applications including furniture, signage, and automotive components.

Acrylic fabrication in Sharjah begins with selecting the right type of acrylic film. There are a number of options available, including polycarbonate (PC), polymethyl methacrylate (PMMA), and polystyrene (PS). PC films are the most common due to their low cost and durability, while PMMA films are ideal for products that require transparency or high-impact resistance. PS films are typically used for products that need to be lightweight or have a flexible frame.

After selecting the type of film, the next step is to choose the appropriate resins. Resins vary in terms of their flexibility, strength, and heat tolerance, so it’s important to select one that will meet the requirements of the project being undertaken. Some common resins used in acrylic fabrication include acrylonitrile butadiene styrene (ABS), epoxy resin, urethane resin, and silicone rubber.

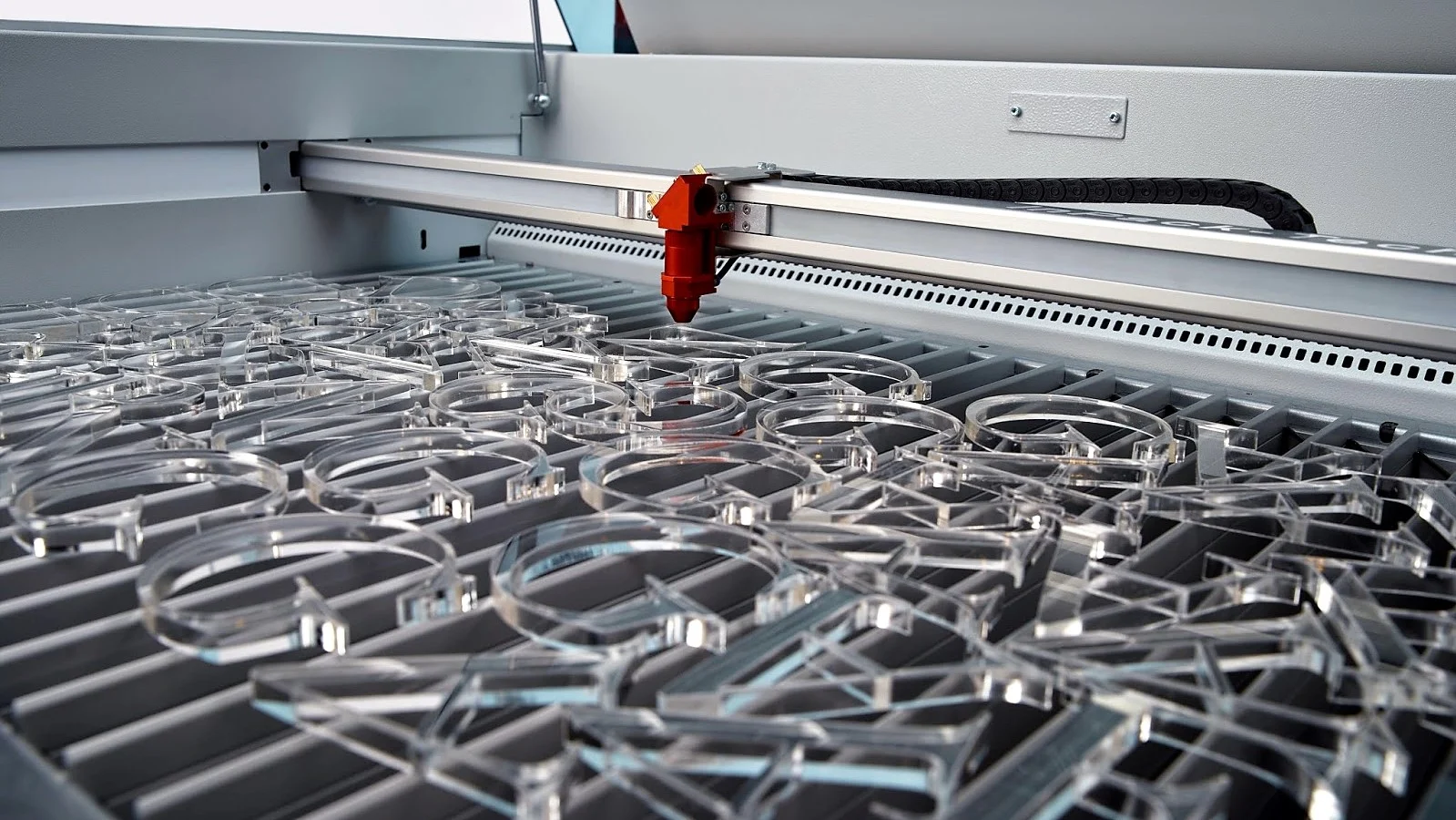

Once the correct resin has been selected, it’s time to begin cutting out the desired pieces of acrylic fabrication. Acrylic fabrication is usually done using a cutting machine known as a CNC router.

Once the pieces have been cut out, they are then cleaned and prepared for the next step in the process: heat welding. Heat welding is a process that uses heat and pressure to fuse the pieces of acrylic together.

The final step in acrylic fabrication is finishing touches, such as painting or adding logos or text.

Acrylic fabrication in Sharjah

Acrylic fabrication is a popular choice for many businesses and individuals in Sharjah because of the wide range of colors, textures, and finishes that can be created. Acrylic sheets are often used to create signs, displays, window panes, and other decorative items.

One of the most common methods for producing acrylic sheets is by using a laser to cut the pieces out of a large block of plastic. The blocks are then chopped into smaller pieces, which are heated until they melt and form liquid polymer strands. These strands are then forced through tiny holes in a spinning drum and formed into small sheets.

Types of Acrylic Fabrication

There are a few types of acrylic fabrication that can be done in Sharjah. These include:

1) Lightweight Acrylic Fabrication: This is where acrylic sheets are cut to size and then assembled into products such as boards, panels, and fabrications using adhesives and mechanical fasteners.

2) Mediumweight Acrylic Fabrication: In this type of fabrication, the acrylic sheets are cut into larger pieces and then assembled into products using adhesives and mechanical fasteners. The main difference between lightweight and medium-weight acrylic fabrication is the amount of weight the finished product can support.

3) Heavyweight Acrylic Fabrication: This type of fabrication uses thicker acrylic sheets that are not easily cut or folded into smaller pieces. The finished product typically has a more pronounced texture due to the increased thickness of the sheet.